Cross-laminated timber, or CLT, is a growing industry in the Southern United States with southern pine and other soft woods abundantly found in the region. Using CLT has numerous benefits economically and environmentally, thereby showing promise for many industries, including developers and contractors, architects and engineers, as well as foresters and landowners.

About CLT

WHAT IS CLT?

Cross-laminated timber, also known as CLT or CrossLam, is a prefabricated wood panel that is made by crossing an odd number of layers of wood stacked crosswise (thus, the name) in alternating directions (perpendicular to each other) which is then glued and pressed into place. This formation gives exceptional strength while being very light compared to other construction materials. Dimensions of finished panels can vary, but are typically two to 10 feet wide, up to 20 inches thick and up to 60 feet in length. It is in a new class of timber products known as massive or “mass” timber, which is often used synonymously with the term CLT; however, the category of “mass” timber includes other engineered products, too, like glue-laminated timber, or GluLam, and nail-laminated timber, or NailLam.

WHY USE CLT?

Sustainability is one of the main reasons’ architects, engineers and construction professionals are seeking out CLT for their projects. Wood is a renewable source that sequesters carbon, thereby having a positive or neutral carbon footprint. Also, the cross-laminating process provides improved dimensional stability so that “massive” timber (long, wide floor and ceiling slabs and high, single-story wall panels) can safely be used. In addition, contrary to what one might believe about wood products, CLT has a very good fire rating due to the thickness and cross-section pattern. Furthermore, because it is designed and cut to specifications at the manufacturing facility before being delivered to the jobsite, the measurements tend to be more accurate and, consequently, CLT is easy to install, with little waste and faster construction times. Finally, CLT is cost competitive to other building materials due to savings in lower transportation costs, reduced installation times and earlier completion dates.

IN THE WORLD OF CLT

Cross-laminated timber, or CLT, was initially used in Germany and Austria in the early 1990s as an alternative to stone, masonry, and concrete construction. The first national CLT guidelines were published in 2002, which spurred the acceptance of CLT as a building material for multistory buildings throughout Europe. Its use finally found its way to Canada and the Pacific Northwest of the United States about 10 years ago. The first CLT-constructed building to be completed in Alabama is the Candlewood Suites at Redstone Arsenal near Huntsville which opened in March 2016. It is also the first hotel in the U.S. to be completely constructed using CLT. Four years later, Alabama now has three buildings that were constructed using CLT and 10 more in the design phase. And this is only the beginning. There is increased momentum for building with CLT and other mass timber. In fact, according to WoodWorks, as of March 2020, 784 mass timber projects had been constructed or were in design in all 50 states, in the multifamily, commercial, or institutional categories.

CLT in the News

New York approves use of cross-laminated timber for 6-story buildings

San Francisco’s first cross-laminated timber building is complete

Why not construct multi-story buildings out of wood?

A 145,000-square-foot cross-laminated timber building is coming to downtown LA

This old building material is new again

A Maine-based cross laminated timber factory could mean more affordable housing

CLT Conference News

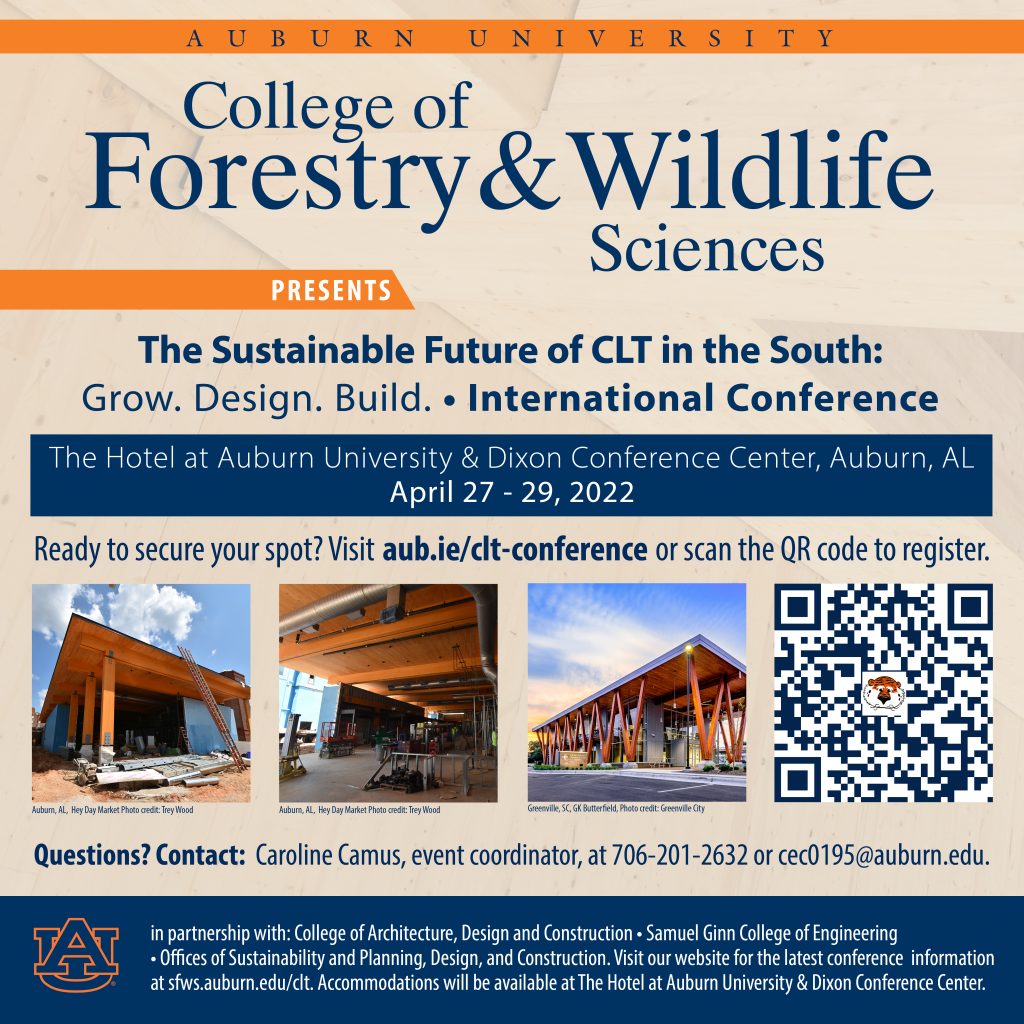

The Auburn University College of Forestry and Wildlife Sciences, in partnership with several other academic colleges and administrative offices, will host the first cross-laminated timber, or CLT, international conference ever to be held in the southern United States next month at The Hotel at Auburn University and Dixon Conference Center.

The three-day event titled ‘The Sustainable Future of CLT in the South: Grow. Design. Build.’ to be held April 27 – 29, will feature renowned experts in forestry, building sciences, engineering and architecture and design who will share the latest CLT research, trends and developments in the South.

Session tracks will offer information to address the needs of multiple audiences, including designers, builders, contractors, academia, landowners, producers, and suppliers.

More information about registration, speakers, sessions, and sponsorship are available online or contact Caroline Camus at (706) 201-2632 or email cec0195@auburn.edu. Accommodations will be available at The Hotel at Auburn University & Dixon Conference Center.

The conference is presented in partnership with the Auburn University College of Architecture, Design, and Construction, Samuel Ginn College of Engineering, and the Offices of Sustainability and Planning, Design, and Construction.

Adam Maggard

Extension Specialist & Harry E. Murphy Associate Professor, Forest Systems Management

Maria Soledad Peresin

Associate Professor, Forest Biomaterials; Adjunct Professor, Chemical Engineering